Creating

the Future of

Plating

R&D

Support

The components of today’s devices have become so miniaturized that many require an electron microscope to observe. These microscopic parts require surface treatment to impart a variety of attributes, such as electrical characteristics, strength, corrosion-resistance and heat-resistance.

In many cases, special alloys are required to make these components, rendering surface treatment especially challenging.

FlabR, Inc. excels in research and development on surface treatment to meet the needs of the world’s most advanced electronic components, and in the development of related manufacturing processes.

Our Strength

-

01

Adding Value Through Plating Born of Specialized

Metal material ResearchFlabR conducts dedicated research not only on the film properties of plating, but also on Metal material, and applies that research to plating.

Our research encompasses material mechanics, changes in composition from thermal reactions, crystalline structure, interfacial reactions, strengthening mechanisms and more. By integrating this technical knowledge into plating, we achieve value-added that others cannot match. -

02

Achieving the desired characteristics in ultrafine components requires

dedicated fabrication methods and equipment.FlabR brings together technological strengths that can breathe life into the entire series of events from concept development, planning and design through prototyping and prototype evaluation.

These processes are implemented through repeated trial and error. FlabR’s advantage is that the Company applies statistical modeling to deduce results theoretically. -

03

Advanced Analytical Technologies Incorporate a Host of

Characteristics and FactorsResearch and development of plating for ultrafine components requires strengths in analytical technology. FlabR excels in analytical technologies that elucidate the crystalline structure, organization, constituent phases and connective structures of metals on the theoretical level, drawing on comprehensive analysis of metals’ mechanical, electrical and chemical properties and factors such as corrosion, fatigue and the friction and abrasion generated by the mechanical joining of components.

Technical

Information

The components of today’s devices have become so miniaturized that many require an electron microscope to observe.By plating these ultrafine components, it is possible to impart attributes to them such as electrical characteristics, strength, corrosion resistance and heat resistance.

In many cases, special alloys are used to fabricate these ultrafine components, creating special challenges for plating. To support the world’s most sophisticated electrical components, we at FlabR conduct our own development, including manufacturing techniques, excelling in research and development of plating using precious metals.

Generally, plating is conducted by adding copper, nickel or precious metals such as silver or gold to metal or plastic surfaces. These surface metals not only make the component more aesthetically pleasing but also add functionality such as corrosion resistance or electrical conductivity.

In recent years electronic devices have relentlessly become smaller and more high-performance. In turn, the electronic components used in them are becoming extremely tiny.

Against this background, the features required of plating have become more extensive and demanding. Manufacturers today demand plating that makes their electronic components not only corrosion-resistant and electroconductive but also hard and heat-resistant. High-spec features are even required for materials that are difficult to use in plating.

The FlabR Advantage

-

01

New and Special Value-Added

FlabR works with customers on research to develop solutions to difficult challenges, such as value-added that has never been achieved before, or incorporation of multiple properties into a single material. The Company is especially proficient at plating of ultrafine components included in the contact probes used in semiconductor testing equipment.

-

02

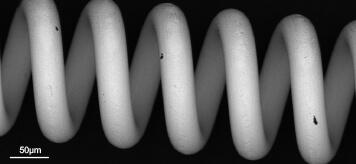

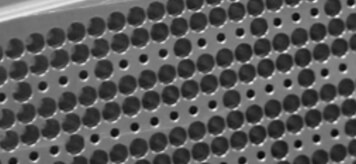

Parts That Require Multiple Ultrafine Perforations

Ultrafine perforations are those with diameter as small as 50µm. FlabR electroplates these perforations, including inner surfaces, with uniform functionality.

-

03

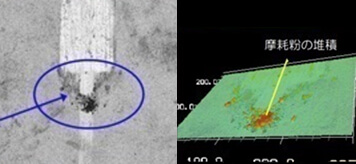

Reducing Abrasion to Improve Durability

When components rub against each other, tribology—the science of interacting surfaces—comes into play. FlabR selects and finely adjusts coating materials to create coatings wth tribological functions, such as reduction of surface abrasion and expulsion of dust from abrasion.

Technical Information 02

Technologies for Analyzing Products

in Development and Defective Products

When testing products in development, developers encounter a wide range of phenomena. If they fail to elucidate the mechanisms by which those phenomena occur, developers cannot proceed to the next step. This reality makes analysis of existing products essential.

Similarly, when defects occur, developers must analyze them to elucidate their mechanisms.

That analysis must be conducted using the correct analytical methods and equipment, or accurate assessments will be impossible to reach.

Conducting analyses in the correct order is vital. Analyzing phenomena in the wrong order can lead to failure to elucidate mechanisms correctly.

Selecting the right analytical equipment and analytical technologies is important for elucidating the causes of defects in the development process.

The FlabR Advantage

-

01

Observation using Scanning Electron Microscopes and Scanning Probe Microscopes

A scanning electron microscope (SEM) is a device that focuses a beam of accelerated electrons on a specimen and moves the beam around to observe the form of the specimen’s surface.

A scanning probe microscope (SPM) is a device that physically interrogates a specimen with a microscopic probe to observe its surface shape and properties. An SPM can resolve images down to the molecular and even the atomic level. -

02

Analysis Using an X-Ray Fluorescent Analysis Thickness Meter or an Inductively Coupled High Frequency Plasma Source

An X-ray fluorescent analysis thickness meter is a device that measures film thickness by measuring as an X-ray dose the energy generated when electrons are excited or ejected from atoms and then returned to a stable state.

An inductively coupled high frequency plasma source (ICP) excites the atoms of elements in the specimen using plasma energy. When the excited atoms are returned to a low-energy level, the spectral lines emanating from the specimen are measured. -

03

Analysis of Cross-Sections Using a Focused Ion Beam or

Cross-Section PolisherA focused-ion-beam device (FIB) scans the surface of a specimen using an ion beam to process the specimen surface.

A cross-section polisher (CP) uses an Ar+ ion beam and a ashielding plate to prepare cross-sections of a specimen.

FlabR

at a Glance

- Name

- FlabR, Inc.

- Address

- 317-15 Yanaka Town, Takasaki City, Gunma Prefecture 370-1203 JAPAN

- TEL

- +81-50-5490-7400

- Established

- July 10, 2020

- Capital

- 1,000,000 yen

- Representative director

- Fumio Watanabe

- Correspondent bank

- Nakai Branch, Gunma Bank

At FlabR,

we conduct research focused on metal plating of microscopic parts used in the contact probes of semiconductor testing equipment, consumer connectors and ceramic-chip parts.

In addition to plating, the Company conducts research in material mechanics, changes in structure from thermal reactions, crystalline structures, interface reactions and strengthening mechanisms. By applying the resulting technical knowledge, we achieve unprecedented value-added.

Count on FlabR for solutions to all your plating issues and concerns.